Bricks | Unistara

Brick kilns

The technological and design solutions implemented by Unistara in the last 35 years have deeply influenced the brick kilns sector. The products manufactured to Unistara specifications, the strategic position of the branches and a technical structure specialized in this type of industrial installations have been the determining factors for the evolution of this market.

Main products

Unistara’s offer, addressed to the brick sector, includes:

Drawn products

In cordierite and cordierite mullite such as plates, supports and various shapes.

Pressed refractory shapes

Semi-dry, silica-alumina or semi-cordieritic, for the construction of cars and vaults.

Fibrous and non-fibrous insulating products

Papers, felts, mats and slabs based on artificial glass fibres, rock wool and calcium silicate for furnace linings, bogie covers, expansion joints.

Insulating bricks

High compressive strength and insulating bricks in ASTM 23-32 classes.

Insulating concrete

Lightweight and extra-lightweight for the insulation of traditional vaults and cars.

Special pieces

Traditional and column supports, burner blocks heat-treated in high-temperature furnace.

Main services

The service offered to the furnaces begins with the technical-commercial inspection of the operating conditions and wear of the installation, as well as the recognition of production requirements. Unistara’s technical structure designs the complete lining of the brick kilns, or the bogies only, also providing the solutions to increase the efficiency of the systems, for example, optimizing the insulation or increasing the internal light and thus extending the life of the lining.

Installations Gallery

Video

Types of installations

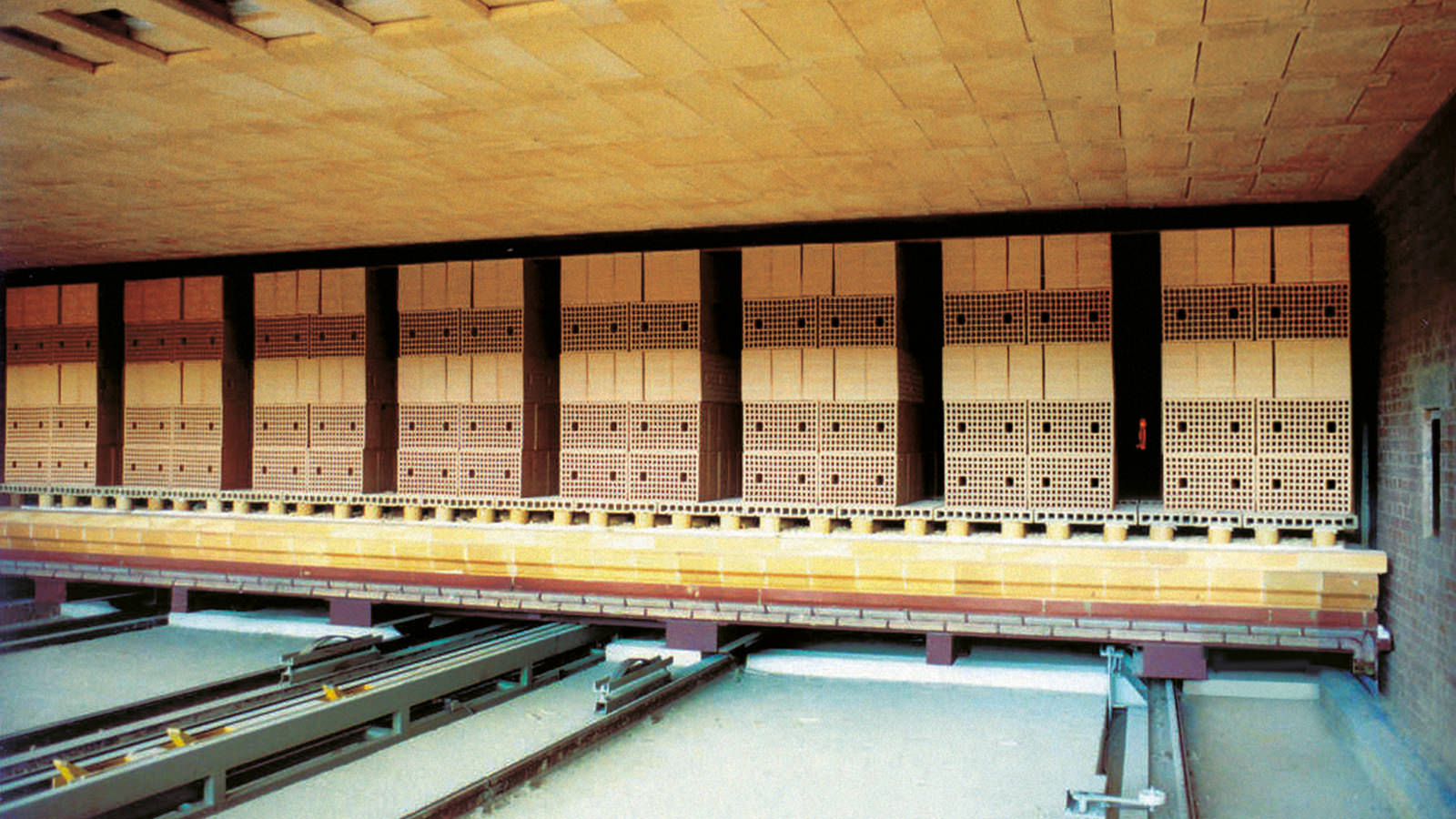

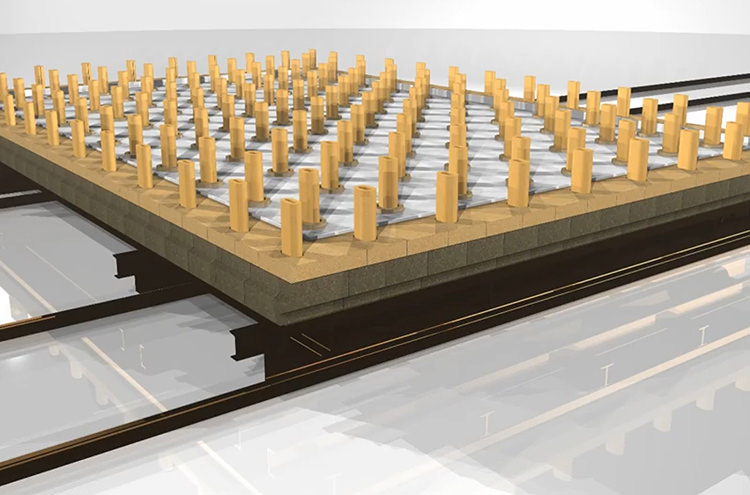

Kiln cars

Characterized by simple and modular construction, rational distribution of the load-bearing structure and reduction of the weight of the refractory lining. The loading surface, in addition to guaranteeing absolute homogeneity, provides for the use of protective barriers, which, together with a correct distribution of expansion joints, drastically reduce the infiltration of brick flakes and energy dispersion.

Vault furnace

The materials used for the building of the vaults meet high-quality standards and are characterized by a linear geometry that, thanks to the uniformity of pressing, ensures a longer life. The design solutions adopted for standard or lightened flat vaults allow to reduce dispersions and increase the energy efficiency of the system.

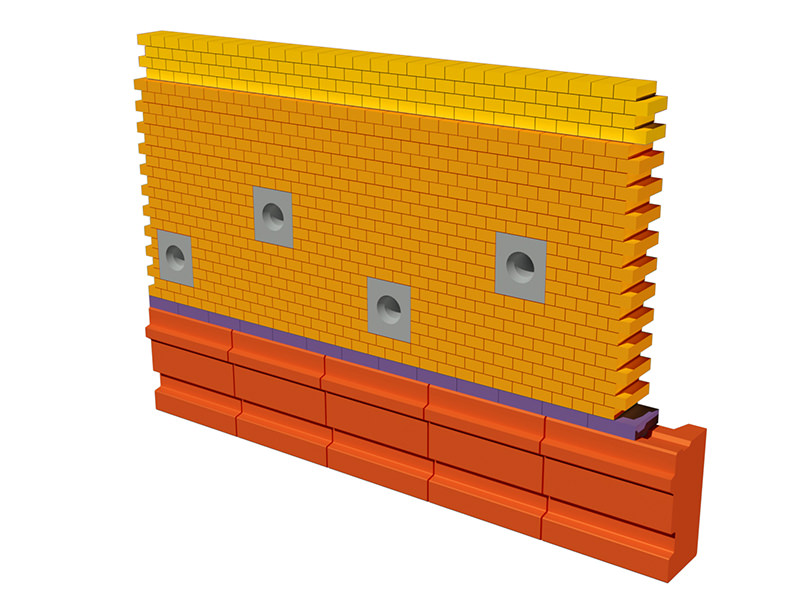

Masonry

High aluminous and antacid refractory materials are used for the walls of the kiln, which are able to resist chemical aggression that vary according to the type of clay used. When the structure of the furnace requires it, Unistara produces the special pieces and anchors needed to complete the masonry.

Vault and wall insulation

The study of the insulating lining of the installation starts from the calculation of the thermal dispersion of the furnace and proceeds to the definition of the type and thickness of the insulation in order to reduce energy consumption or increase the production capacity with the same consumption.